I-SMT, ebizwa nangokuthi iphepha lokusula le-SMT elizenzakalelayo, iphepha lokusula i-SMT, i-SMT elingenalo uthuli iphepha, iphepha lokusula le-SMT, njll. Iphepha lensimbi elisetshenziswa ngokuvamile lenziwa ngokhuni lwemvelo lwe-pulp kanye ne-polyester fiber, futhi licutshungulwa ngendlela eyingqayizivele ye-spunlace, ukwakha ukhuni oluyingqayizivele lwe-pulp/polyester ungqimba oluphindwe kabili lwesakhiwo.Ikakhulukazi, iwumkhiqizo ongcono kakhulu wokukhipha i-SMT steel mesh kanye ne-solder paste eyeqile kanye neglue ebomvu ebhodini lesekethe, nokugcina ibhodi lesifunda lingenabala.Ingathuthukisa kakhulu ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.Ukuze uthuthukise ukusebenza kahle kwamakhasimende, gcina izindleko futhi ulawule ukusetshenziswa kahle.Iphepha lokusula linatha lensimbi.

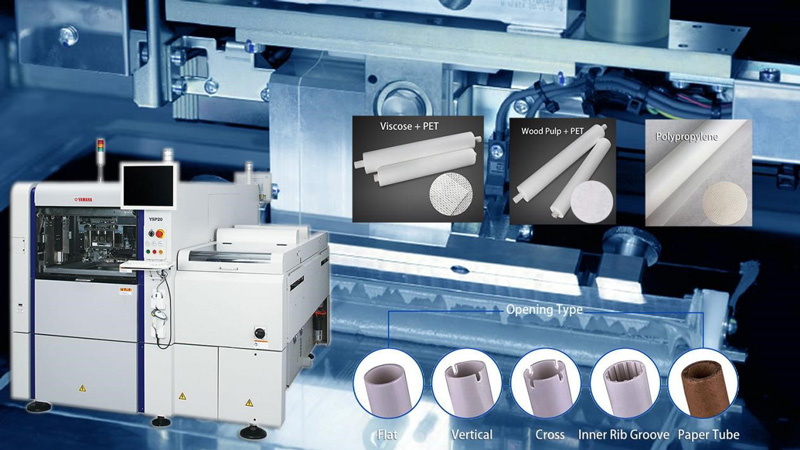

I-SMT steel mesh yokusula iphepha ingahlukaniswa ngezinhlobo ezimbili: iphepha elingenalutho kanye nephepha legridi.Isisindo singu-56-68 g/m2, ukujiya kungu-0.3-0.35 mm, kanti ububanzi buyi-23-200cm.Kunezinhlobo ezimbili zamapayipi omugqa: ipayipi lephepha nepayipi lepulasitiki.Kunezikhala noma azikho izikhala emikhawulweni yomibili yamapayipi asetshenziswa imishini ehlukene yokuphrinta.Ngokuvamile, ingasetshenziselwa yonke imishini yokunyathelisa ezenzakalelayo efana ne-MPM, DEK, KME, YAMAHA, MINAMI, JUKI, EKRA, PANASERT, FUJI kanye ne-SANYO.Ububanzi nobude bephepha lokusula lensimbi yensimbi ye-SMT, nobubanzi nobude bepayipi lomugqa wangaphakathi kunqunywa usayizi wangempela womkhiqizo ophrintiwe kanye nemodeli yokuphrinta.

Okulandelayo yizici eziyinhloko zephepha le-SMT steel mesh lokusula:

1. Ukuqina okuqinile nokuqina.Iphepha le-SMT steel mesh lokusula linomthamo oqinile wokukhangisa emanzini namafutha, elingakhanga ngokushesha nangempumelelo amabala amanzi namafutha ezintweni, ngaleyo ndlela kuzuzwe izici zokuhlanza okuqinile kanye nokususwa kwamanzi ajulile kanye nowoyela.Ngaphezu kwalokho, inokuthamba okungokwemvelo, okungenayo uthuli kanye nemiphumela ephikisana ne-static, futhi uthuli ngeke lwehle ukuze luthambile futhi luthambile lapho lwesula ukungcola, ukuze abantu bakwazi ukulusebenzisa ngokukhululekile, ikakhulukazi endaweni eyomile ebusika, ngeke ikhiqize ugesi omile, futhi ngeke ibangele ukushaqeka kukagesi okuqhutshwayo nokunye ukulimala.

2. Ukuthungwa kuthambile futhi akunangozi.Lolu hlobo lwephepha lokusula lunezici zokuthungwa okuthambile, insimbi kodwa hhayi kanzima.Kungakhathaliseki ukuthi umzimba uthambile noma uqinile, ngeke ubangele imihuzuko noma ushiye imihuzuko neminye umonakalo, ngaleyo ndlela uzuze ngempela umphumela othuthukisiwe wokungabi nangozi emzimbeni.Kufezwe ngokuphelele inani lemali, imiphumela yalokho okungafinyelelwa.

3. Ikhono eliqinile lokumunca uketshezi kanye nokususwa kokungcola okuqinile.Iphepha le-SMT steel mesh lokusula linomthamo ongacabangeki we-adsorption liquid, futhi linamandla okukhangisa aqinile azo zonke izinhlobo zoketshezi, elingafinyelela umphumela wokuhlanza okujulile ngesenzo esisodwa.Ingakwazi ukukhangisa ngokuphumelelayo amabala avamile, amabala angenakunyakaziswa kanye namabala afinyeleleka kakhulu phezulu, ukuze zonke izinhlobo zezinto ezingcolile ziqoqwe futhi zihlanzwe ngokuhlanzekile nangokucacile.Ngaphezu kwalokho, iphepha lokusula alisebenzisi noma yimaphi ama-reagents amakhemikhali, ngaleyo ndlela ifinyelele ukungcola kwe-zero, ukuvikelwa kwemvelo, ukuphepha nokuhlanzeka.

4. Ukusetshenziswa okubanzi kwekamelo elihlanzekile.Njengoba sazi sonke, ikakhulukazi embonini ye-elekthronikhi, izidingo zemvelo ziphezulu kakhulu, zifinyelela endaweni ecishe ingabi naso uthuli, futhi iphepha lensimbi lensimbi le-SMT lokusula linokusetshenziswa okukhulu.Ingakwazi ukuqedela zonke izinhlobo ze-PM nomsebenzi wokulungisa imishini nomshini, futhi ngeke ilimaze futhi ilahle i-slag emishinini futhi ilimaze umshini, futhi ngeke iphinde ingcolise imvelo engenalo uthuli futhi.Nikeza isiqinisekiso esiqinile sezidingo zegumbi elihlanzekile eliphezulu lemboni ye-elekthronikhi futhi uhlangabezane nazo zonke izidingo zokukhiqiza.

I-Beite ihlinzeka ngephepha le-SMT lensimbi lokusula elinezikhala elenziwe nge-PP, i-Viscose+PET kanye ne-Wood Pulp+PET, elingahlangabezana nezidingo zemikhiqizo ehlukene yamaphrinta anamathisela e-solder azenzakalelayo.

Isikhathi sokuthumela: Oct-26-2021